Boatshed Preferred Partners - A day in the life of a Sail Maker!

I recently published a blog explaining how our Preferred Partners Scheme works. As a follow on A day in the life of series was born, starting with.... A day if the life of a Sail Maker!

Mark Flew has been running Flewsails for 25 years from a unit in Wicor Marine hidden almost at the bottom of Portsmouth Harbour.

The business consists of two sail makers Benn and Mark, Heather who looks after the Accounts and assists Mark (the business owner, there are two Marks) who oversees the general running of the business, liaising with customers, working on quotations and working with other marine businesses.

Mark took me on a tour around the sail loft where I found Benn in the process of making 50 spinnaker socks for a large race fleet.

I asked Mark about his business over a coffee in Salt Cafe also in Wicor Marine.

How do you become a sail maker?

You don't need qualifications, but you do need a lot of on the job training and experience. I don't know of any courses that will teach you.

How long does it take to make a sail?

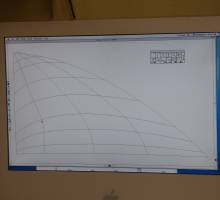

It takes us approximately 2-3 days to make a sail from a design.

Where does Hyde Sails feature in your business?

We are a distributor for Hyde Sails. Hyde have a factory in the Philippines and can provide competitive prices for new sails. Hyde are one of the largest volume sail makers in the world.

What other services do you offer?

A lot of our work consists of sail alterations to improve performance, replace worn sacrificial strips, sail specification changes and spar and roller reefing. We work on anything from a sail for a Fever dinghy to a spinnaker for an Volvo 70 and frequently have some very large contracts for charter co's etc.

New spray hoods and sail covers, restitching and repairs on spray hoods, upholstery etc and laundering, valeting and storage of sails ready for the next season. We also carry out all sorts of industrial jobs for some very large organisations.

What is the biggest job you have ever completed?

A PVC roof for a building, with built in skylights. We also made covers for the buildings for a well know holiday camp.

What is the most expensive mistake you have ever made (I didn't expect Mark to answer this but he did)!

We had a large industrial job which needed £200/metre fabric. When it was delivered, it wasn't right.

What did you do to rectify the problem?

We took it back to the loft and did it again. Luckily a large part of the job could be altered, so it wasn't too bad and the company was very happy with the end result and if the customer is happy, we are happy.

Mark took me along to see one of the Flewsails most recent jobs - Sides to attach to a solid canopy on a converted MFV (see photos below). I met Sam and Dan who live aboard the vessel. Sam said that the awning has made a huge difference to life on board. We now have so much more space and with the addition of the log burner on deck, it means that we can now stay out here whatever the weather. We love it!

Thank you Mark, I really enjoyed my tour around your sail loft and now feel I know much more about what it takes to be a Sail Maker!

To apply for 10% discount on Flewsails products, click here http://www.boatshed.com/preferred-partner/flew-sails/131430/

Written and Published by: Chrissie Capel - Boatshed HQ Team